+86 18660102967 +86 18615518078

info@runh.com

Biomass power generation plant projects have been mature and widely used in China. At present, there are about 1,000 biomass power generation projects built in China. Runh Power, one of the reliable biomass boiler manufacturers, has rich engineering experience and a large number of engineering cases in biomass power plant project design and construction. It has built the first high-temperature, ultra-high-pressure intermediate reheat power generation project in the biomass power generation industry in China and the 80MW biomass power generation plant with the largest single capacity in the country.

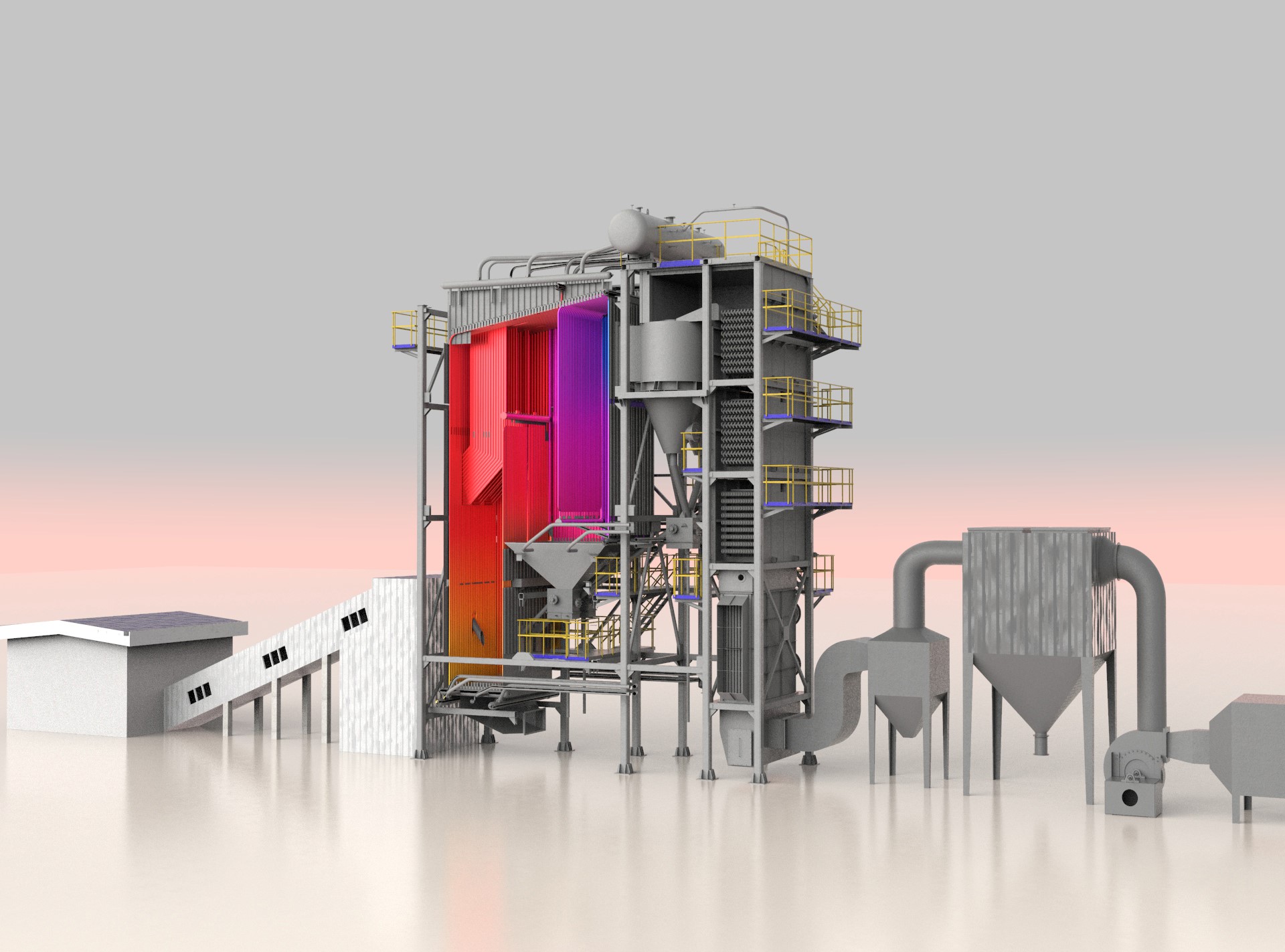

The biomass boiler island mainly includes two categories: biomass grate boiler and circulating fluidized bed boiler, both of which have mature technology and a wide range of engineering applications.

Engineering design

Equipment supply

Installation guidance

Engineering commissioning

The biomass boiler island adopts a simple and reliable system structure, integrating combustion, steam generation, and control units in one platform. This efficient biomass boiler design simplifies installation and ensures stable operation with minimal maintenance requirements.

The optimized biomass power plant design allows a lower initial investment cost while maintaining high performance. Runh, as one of the trusted biomass boiler manufacturers, offers modular layouts that reduce civil construction expenses and shorten the project cycle.

With an advanced combustion system and smart control, the biomass power generation plant achieves lower fuel consumption and reduced manpower costs. Regular biomass boiler island maintenance further improves system reliability and cost efficiency over time.

Runh delivers efficient biomass boiler designs and low-carbon biomass boiler systems that achieve over 90% thermal efficiency. Each biomass power plant project design ensures optimized air distribution and heat recovery for superior performance.

The system supports diverse biomass fuels such as agricultural waste, forestry residues, and molding fuels, making it suitable for various biomass power plants. In cooperation with leading biomass turbine manufacturers, Runh ensures reliable and scalable operation capacity.

Runh focuses on developing low-carbon biomass projects through advanced combustion and emission control technology. Each biomass power plant commissioning process follows strict environmental standards, achieving cleaner energy output and lower carbon footprints.

mainly including bark, branches, wood chips, wood blocks, etc

mainly including various crop straw, peanut husk, rice husk, bagasse, etc

mainly including biomass pellets, biomass briquetting, etc

such as fruits, vegetables, food processing waste, lawn clippings, etc

such as sludge, animal waste, paper and cardboard waste, waste oil

mainly include building formwork, discarded furniture, distilling grains, etc

View More

View More

Lanling Qiquan Biomass power generation project is located in Lanling County, Linyi City, and was put into operation in 2016. The construction scale of the project is 2X130t/h high temperature ultra-high pressure intermediate rehea...

View More

View More

+86 18660102967 +86 18615518078

Block C,Yinfeng Fortune Plaza, No.1 Long'ao West Road, Lixia District, Jinan, China.

Copyright © Runh Power 2025 All rights reserved