+86 18660102967 +86 18615518078

info@runh.com

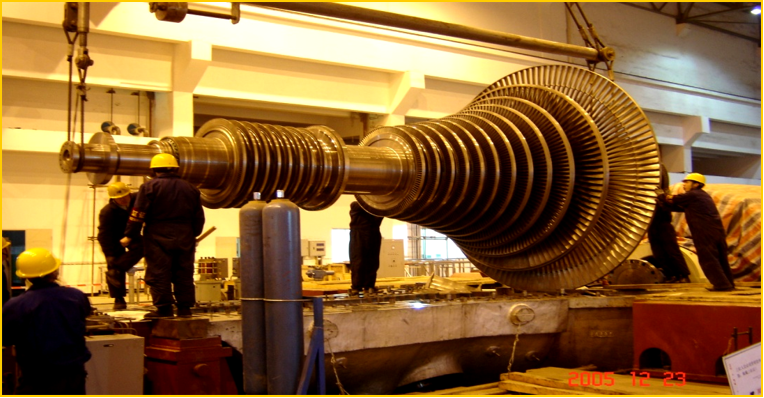

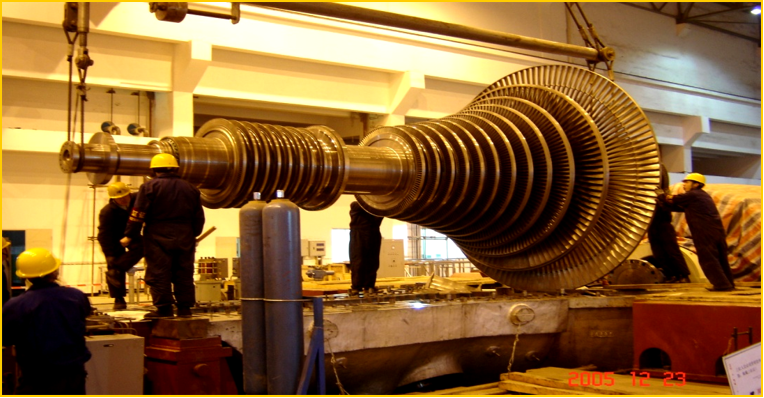

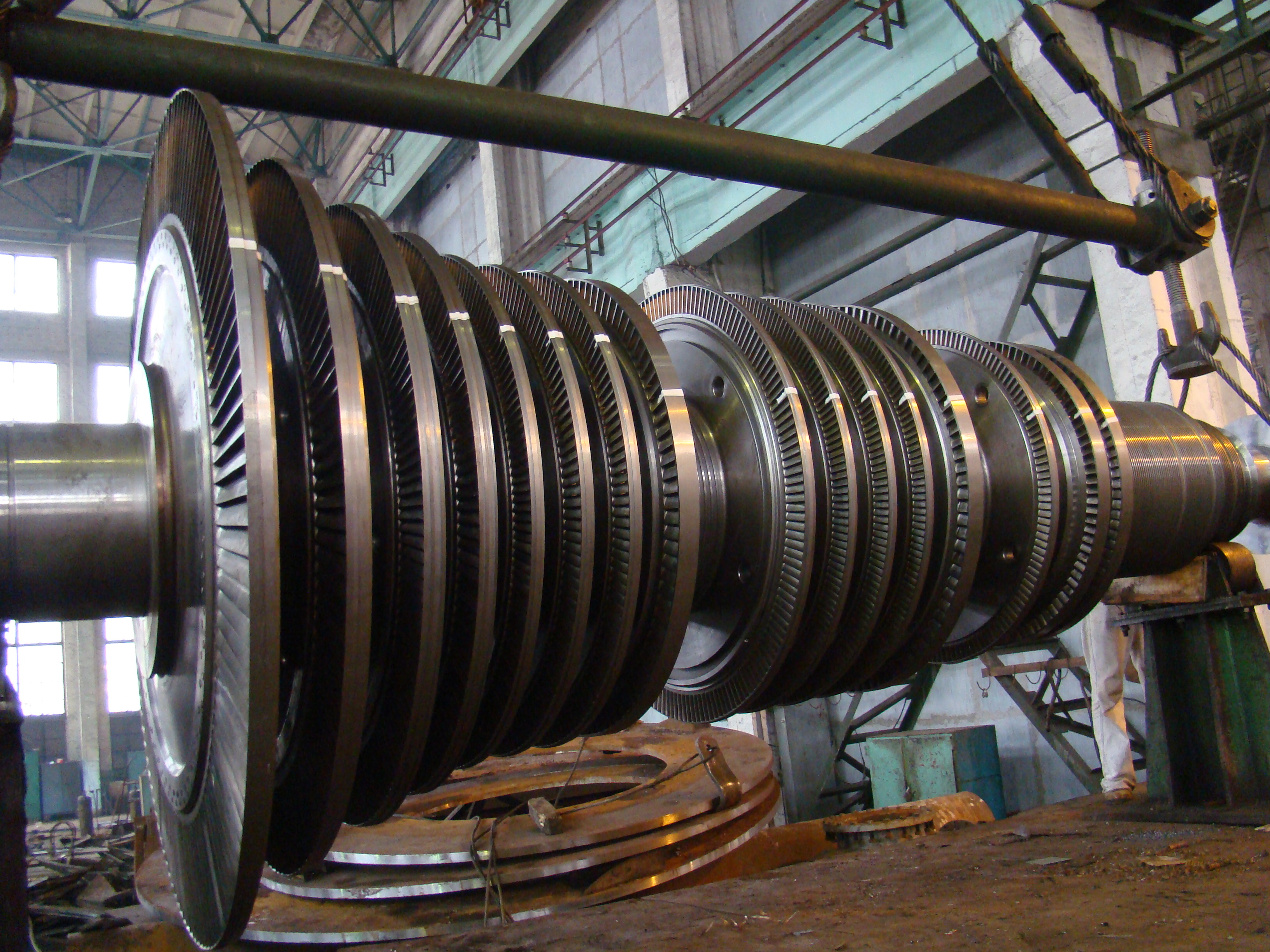

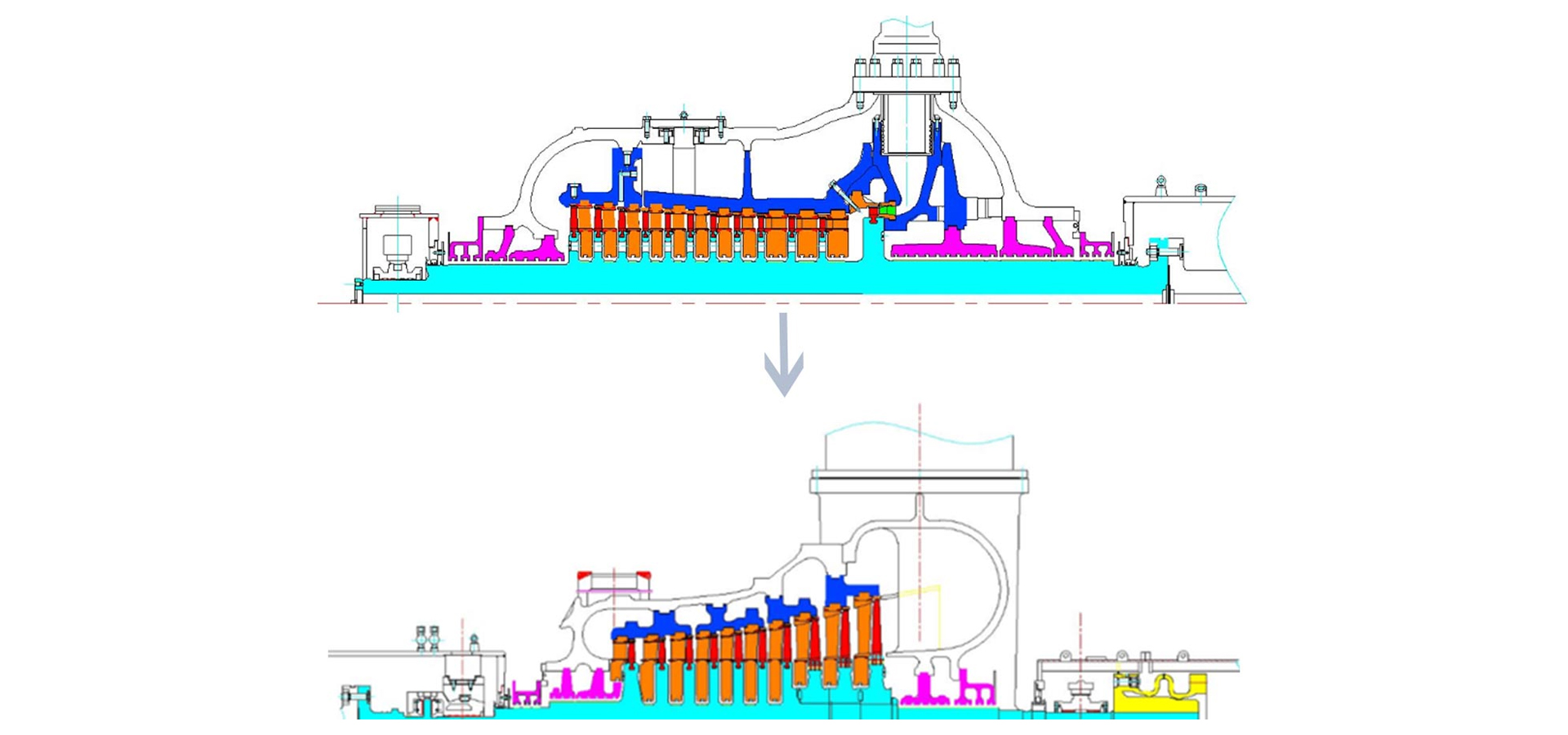

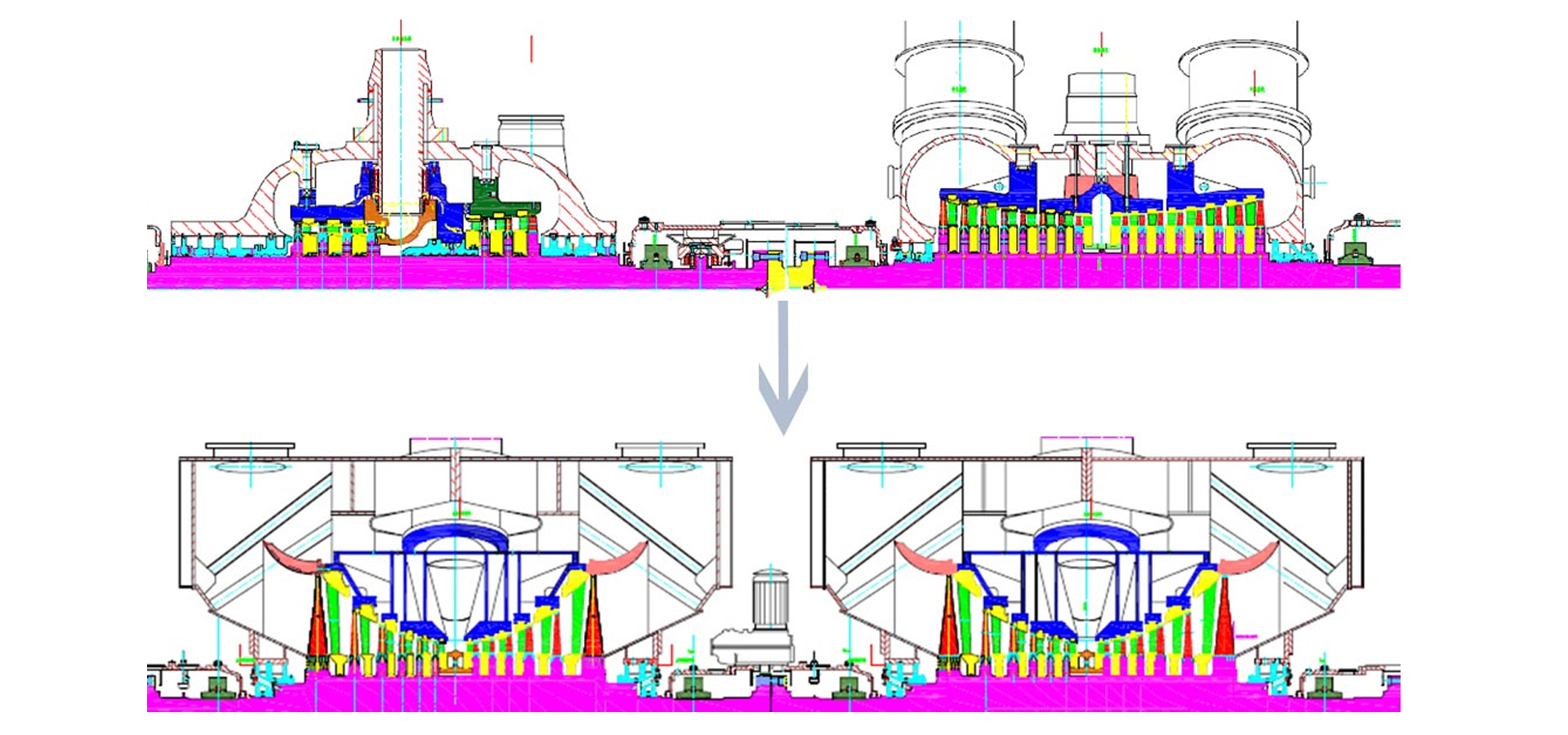

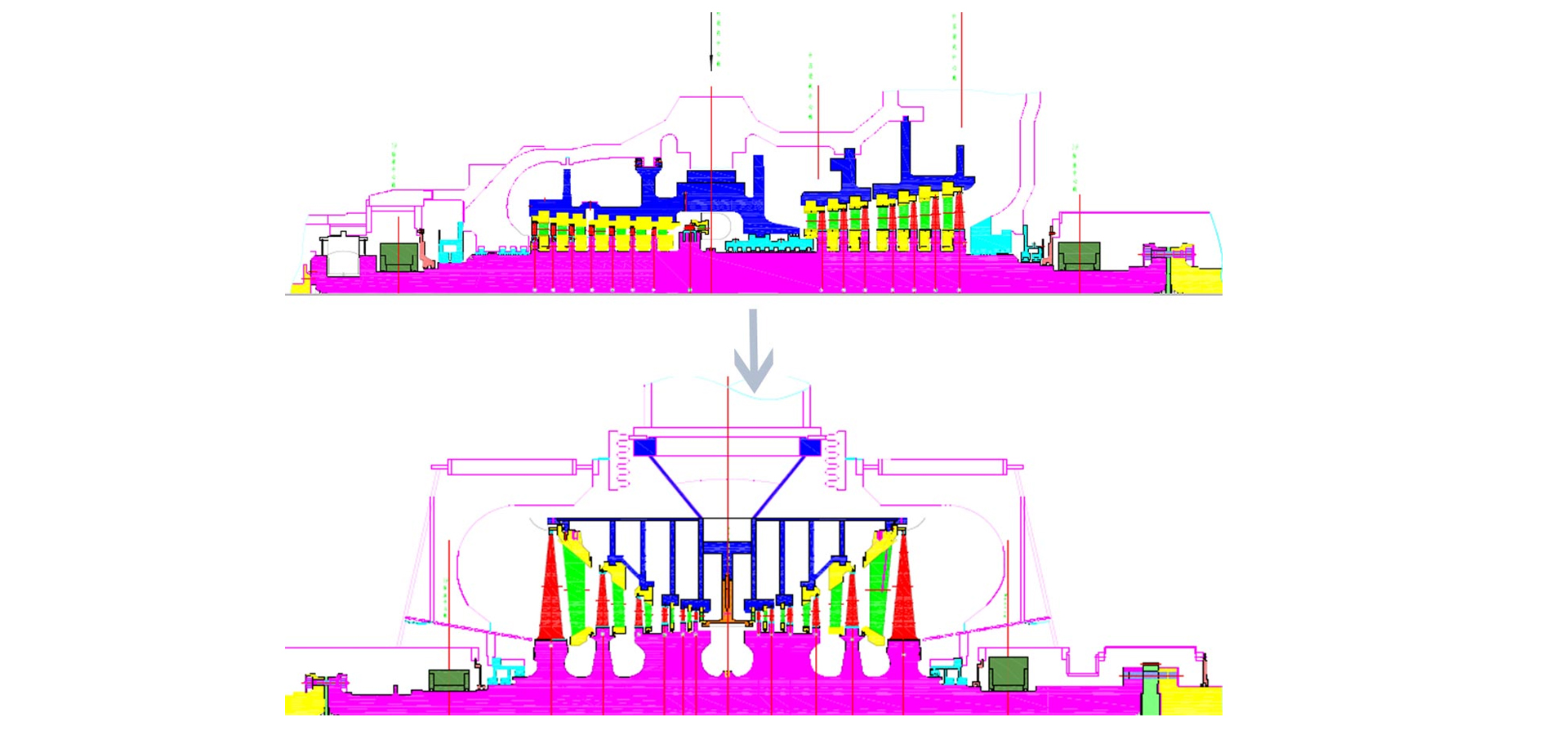

RUNH and its subsidiary, RUNH TG Co., Ltd., have jointly launched a number of steam turbine retrofit technologies, including steam turbine capacity retrofit, steam turbine energy-saving retrofit, steam turbine island system retrofit, steam turbine heating retrofit, and many other unit retrofit technologies. Here is the profile of Runh’s turbine design and manufacturing company — RUNH TG Co., Ltd., formerly a subsidiary of the Chinese Academy of Sciences (CAS). Based on scientific research achievements in turbomachinery aerodynamics and thermodynamics from the Institute of Engineering Thermophysics under CAS, and in cooperation with other founding shareholders such as Tsinghua University, Beihang University, and other research institutes and manufacturing enterprises, RUNH TG has explored the integration of industry, academia, and research for over 20 years. Through these efforts, the company has developed steam turbine design technologies with independent intellectual property rights and contemporary advanced standards, successfully achieving industrialization and market application.

RUNH can carry out technical retrofits for both Russian-made and domestic turbines. Through optimization of steam turbine flow design, the heat consumption of the unit can be reduced by 5–7%, and coal consumption can be reduced by 15–21 g/kWh (up to 30 g/kWh for Russian units). The company has completed hundreds of retrofit projects, achieving thermal performance that meets modern advanced standards.

All varieties of fast supply

high system automation

24-hour timely response

The operating cycle is extended after maintenance

RUNH and its subsidiary RUNH Full 3D Co., Ltd. jointly launched a number of steam turbine transformation technologies, including steam turbine capacity transformation, steam turbine energy-saving transformation, steam turbine island system transformation, steam turbine heating transformation and many other unit transformation technologies.

RUNH can carry out technical transformation of the Russian machine and domestic machine. Through the transformation of the flow design of the steam turbine, the heat consumption of the unit is reduced by 5~7%, and the coal consumption is reduced by 15~21g/kWh (the Russian machine can be reduced by 30 g/kWh). The number of units has reached hundreds, and the thermal performance has reached the modern advanced level.

With rich experience in turbine and generator maintenance and overhaul, professional vocational training and project management, we are competitive on solving problems and defects of products involved.

RUNH established a close relationship and cooperation with well-known power generation equipment enterprises at home and abroad (GE, Siemens, HEC, DEC, SEC, etc.). Under the guarantee of strict and sound supplier management system, mature end customer service and return visit system, we serve customers all over the world high-quality spare parts under various technologies at a reasonable price.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

+86 18660102967 +86 18615518078

Block C,Yinfeng Fortune Plaza, No.1 Long'ao West Road, Lixia District, Jinan, China.

Copyright © Runh Power 2025 All rights reserved