+86 18660102967 +86 18615518078

info@runh.com

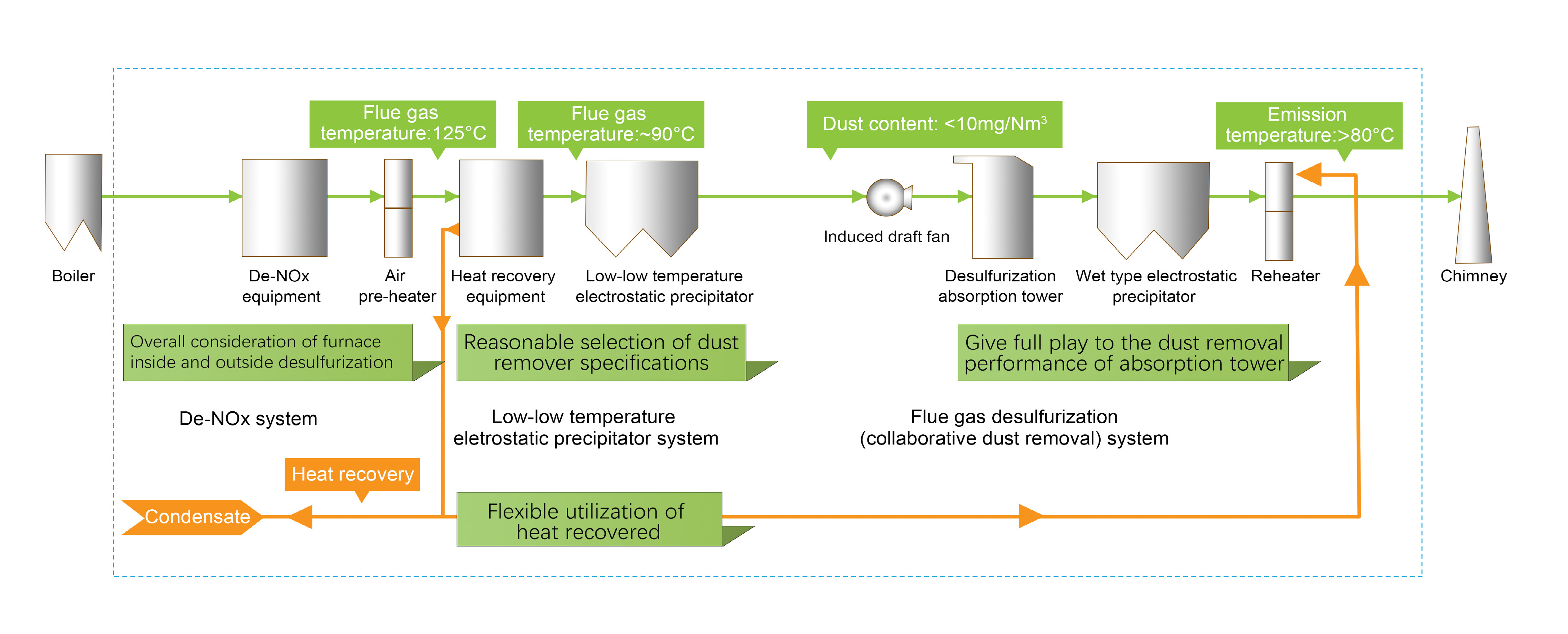

The scope of the power plant green island is from the flue gas outlet of the boiler to the inlet of the stack, and mainly includes desulfurization (collaborative dust removal), de-NOx, electrostatic precipitator, system.

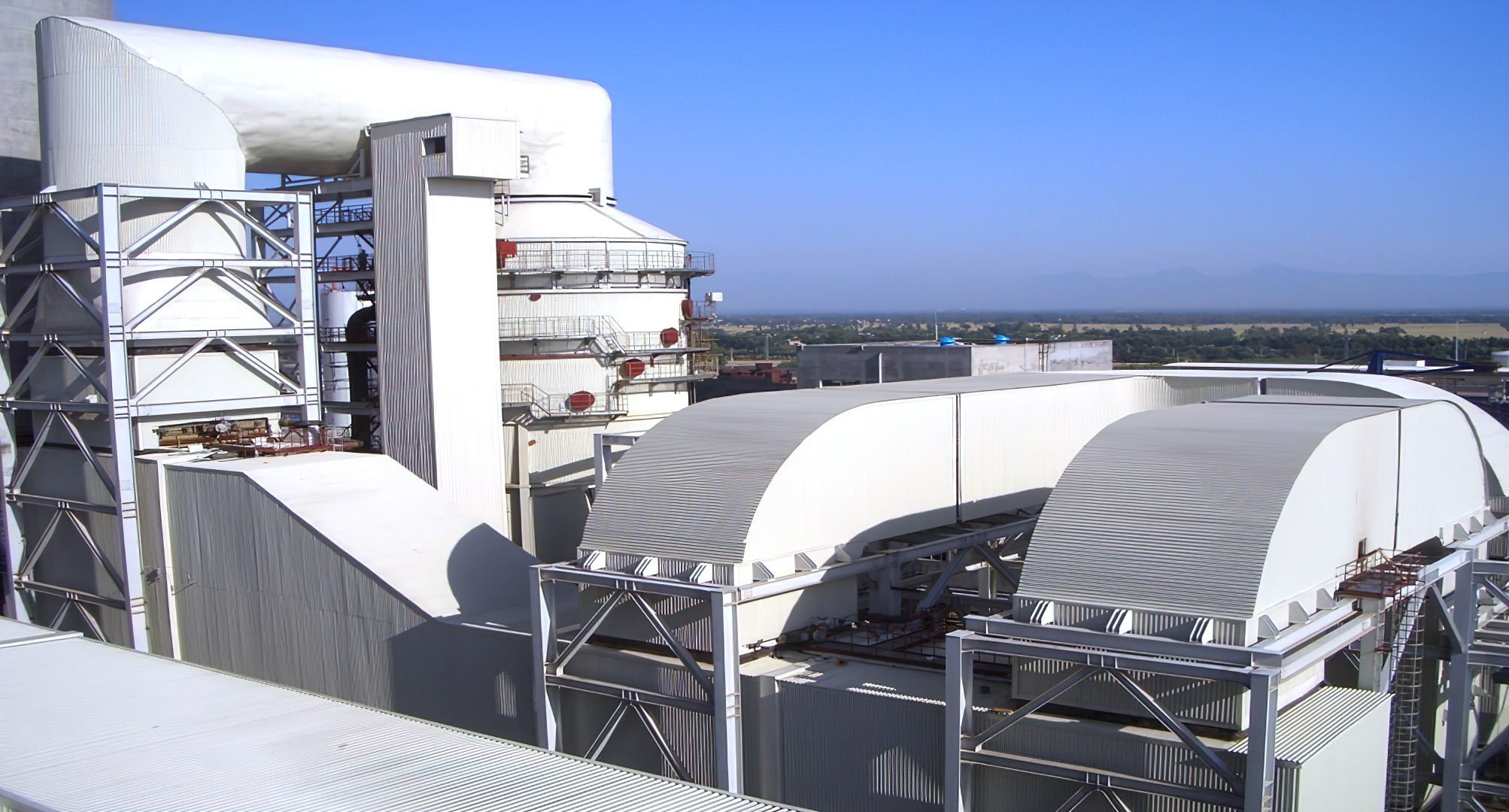

Circulating fluidized bed flue gas desulfurization is a kind of desulfurization and absorption reactor using lime as absorbent and circulating fluidized bed. It makes full use of the unique characteristics of circulating fluidized bed, including the superior heat and mass transfer between gas and solid phases. The absorbent circulates for many times and the contact reaction time is longer, which greatly improves the utilization rate and desulfurization efficiency of the absorbent.

Simple process and low investment

Small floor area and low cost

High desulfurization efficiency >90%

SO3 completely removed

No flue gas reheat system is required

Simple process and low investment

Remove heavy metals without pollution

Agitator is not required in the tower

Use pulse stirring to lift the solids at the bottom of the tower

simple structure

the suspension pump is outside the tower

high oxidation efficiency

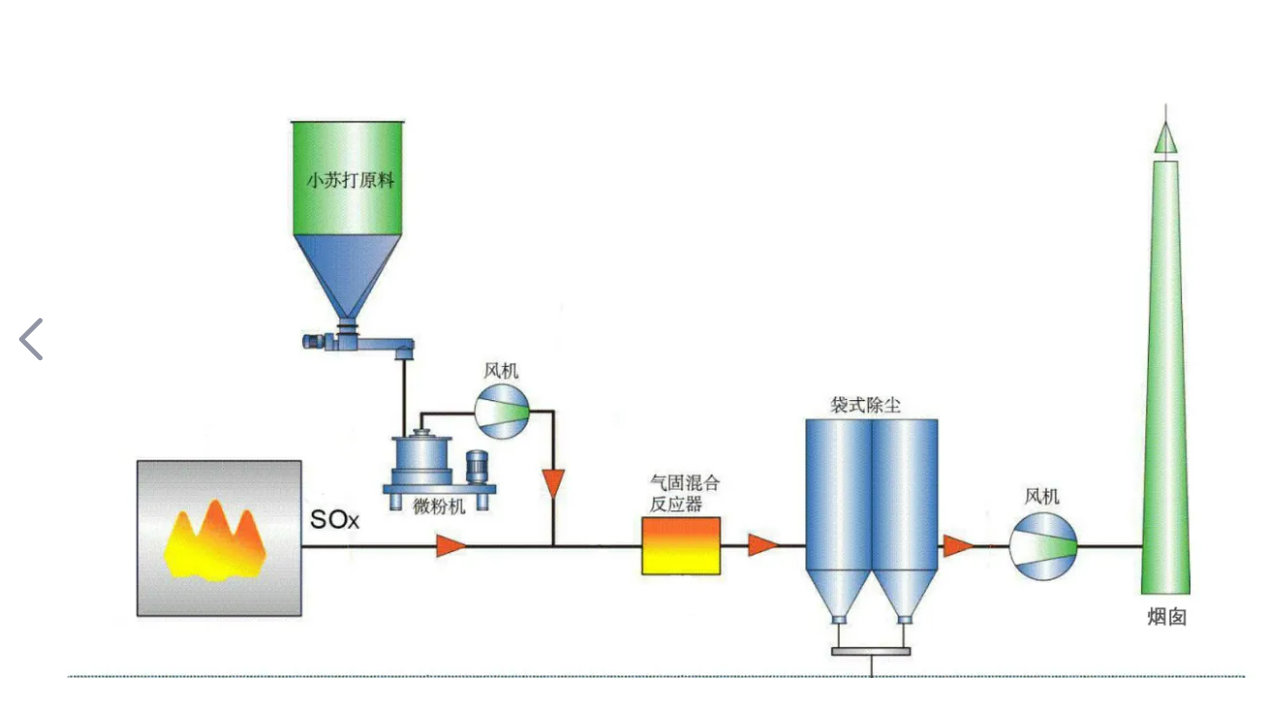

Sodium-based dry desulfurization technology uses NaHCO3 as desulfurizer, which is sprayed into SDS reactor in the state of ultrafine powder. Under the action of high-temperature flue gas, NaHCO3 ultrafine powder decomposes high-activity Na2CO3 and CO2. Na2CO3 with strong activity fully contacts with SO2 and other acidic media in flue gas, and is absorbed and purified.

High efficiency, SO2 removal rate is over 95%

Dry system, no water required

Small floor area, low system cost

No corrosion during the process

Low sulfur content and small flue gas volume

+86 18660102967 +86 18615518078

Block C,Yinfeng Fortune Plaza, No.1 Long'ao West Road, Lixia District, Jinan, China.

Copyright © Runh Power 2025 All rights reserved