+86 18660102967 +86 18615518078

info@runh.com

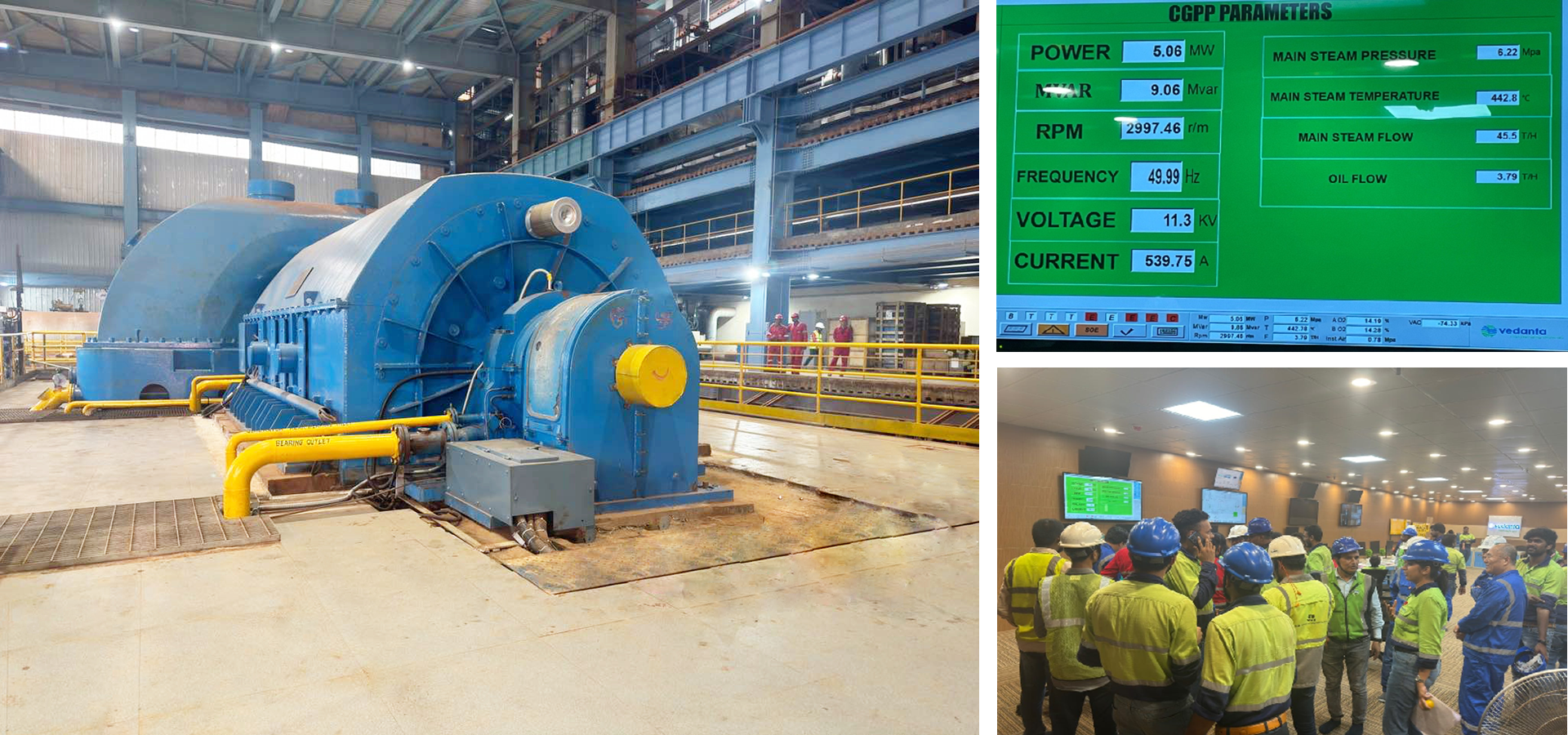

Recently, Runh Power Corp., Ltd( hereinafter referred to as Runh), received the good news from the Vedanta Lanjigarh 130MW Retrofit Project in India. After a series of rigorous and meticulous commissioning and testing procedures, Unit 1 successfully interconnected with the grid at 17:25 on March 22nd, 2024. This achievement marks the successful completion of the first phase of the project, representing a significant step forward.

Unit 1 Successfully Connected to the Grid on Its First Attempt

Phase One Achieves Complete Success

The Vedanta Lanjigarh 130MW Retrofit Project in India comprises two sets of 50MW units and one set of a 30MW unit. Over a decade ago, this power plant construction was halted before completion, leading to the prolonged idleness of a vast amount of equipment. As a result, a severe asset wastage situation emerged at the site, with numerous steel structures, electrical equipment, and accessories turning into scrap metal.

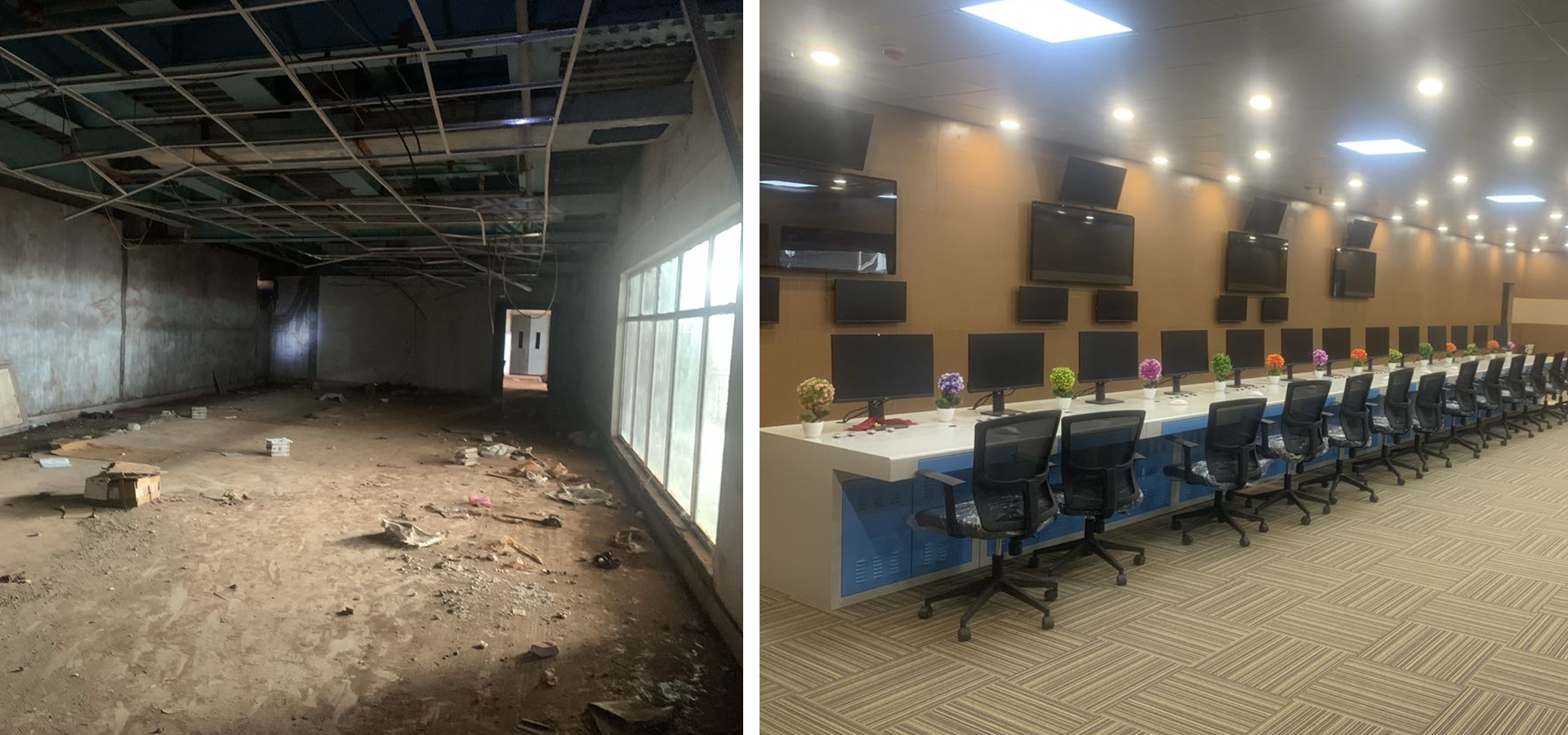

Power plant original appearance

In 2021, Runh formally signed the contract for the Vedanta Lanjigarh 130MW Retrofit Project. Upon entering the initial stage of the project, the project team confronted substantial challenges. The site was littered with remnants of outdated equipment from over ten years ago, which remained uninstalled, rendering the environment derelict and untended. To tackle this issue, the dedicated rehabilitation team from the Source and Retrofit Project launched a concerted effort to revive the dormant power plant assets, with the objective of repurposing them into practical and efficient power generation capacity.

On-site equipment collection and organization

Runh Retrofit Project's special taskforce began by conducting a comprehensive on-site investigation and equipment inventory, meticulously sorting out a list of usable equipment, and making preliminary evaluations of their conditions. They categorized, labeled, and properly stored each piece of equipment. Through these actions, they aimed to systematically understand and manage the existing resources, laying the groundwork for reactivating the dormant power plant.

On-site equipment collection and organization

On-site equipment collection and organization

For the initially screened reusable equipment, the project team undertook in-depth maintenance works, encompassing tasks such as thorough cleaning, corrosion prevention measures, replacement of worn-out components, and repairs to damaged areas. These efforts were taken to ensure that the equipment met stringent safety and stability standards necessary for operational readiness. By doing so, the team aimed to transform the once-idle machinery into reliably functional units contributing to the rejuvenated power generation capacity.

On-site equipment maintenance and repair

In line with new design specifications and engineering technology requirements, the original power generation units underwent reinstallation, integrating necessary new technologies and equipment to meet contemporary environmental protection, safety, and high-efficiency standards. This process involved not only reinstalling the refurbished legacy equipment but also adapting and enhancing it with cutting-edge solutions to optimize performance and compliance with today's stringent regulatory norms.

On-site equipment installation and optimization

On-site equipment installation and optimization

On-site equipment debugging, testing, and experimentation

On-site equipment commissioning, testing, and experimentation

After passing rigorous and meticulous testing and acceptance, Unit 1 successfully is connected to the grid at 17:25 on March 22, 2024, marking the successful completion of the first phase of the project and taking a solid step forward.

Through the tireless efforts of Runh Retrofit Project Task Force, what was once discarded scrap metal has been given new life. They successfully revitalized these "waste materials," implementing reuse, renewal, and recycling, thus transforming them into valuable assets and putting them back into operation.Looking ahead, we will steadfastly uphold the spirit of "Sincerity, Innovation, Efficiency, and Perfection." Runh is committed to tackling more challenges, creating greater value for clients, and making even more significant contributions to society.

Grid Connection on the First Attempt

Power Plant Control Room - Old Look Transformed into New Splendor

Integrated Pump House - Old Look Transformed into New Splendor

Demineralized water pump House - Old Look Transformed into New Splendor

Water Treatment Workshop- Old Look Transformed into New Splendor

Desalination Water Tank - Old Look Transformed into New Splendor

Fuel Pump Room - Old Look Transformed into New Splendor

Compressor Room- Old Look Transformed into New Splendor

Induced Draft Fan Flue - Old Look Transformed into New Splendor

On-site Office Road - A New Lease on Life for Former Appearance

Coal Conveying Belt Conveyor No. 5-Old Look Transformed into New Splendor

Coal Conveying Pipe Conveyor No. 7&8 - A New Lease on Life for Former Appearance

Steam Turbine No. 1 - A New Lease on Life for Former Appearance

Boiler No. 1 Exterior View

+86 18660102967 +86 18615518078

Block C,Yinfeng Fortune Plaza, No.1 Long'ao West Road, Lixia District, Jinan, China.

Copyright © Runh Power 2025 All rights reserved